May 30, 2024

If we don’t take automation seriously, our competitors will. This article explains how we do it at kommit, preventing us from wasting resources.

A recent report in the MIT Sloan Review showed the numbers obtained by AT&T’s “Project Raindrops.” This initiative, which started in 2020, saved the company $230 million. Outstanding. At AT&T, “Raindrop” is a metaphor referring to “an annoying policy, an outdated process, or a tool that’s no longer useful.” One or two raindrops are bearable; thousands inundate the company with inefficiencies [1].

The report resonated deeply with me because, at kommit, we use a similar metaphor referring to process automation. We favor small automation (drops) over huge and complex automation workflows. We strive for the compounding efficiency of many small automation cases. We call such an initiative the BAS— Business Automation Suite.

Whether AT&T with their Raindrops Project or at kommit with our BAS, the goal behind these initiatives is clear: tackle operational inefficiencies to stop losing money.

At kommit, our approach to automation is based on the following reasoning:

We also made two strategic decisions:

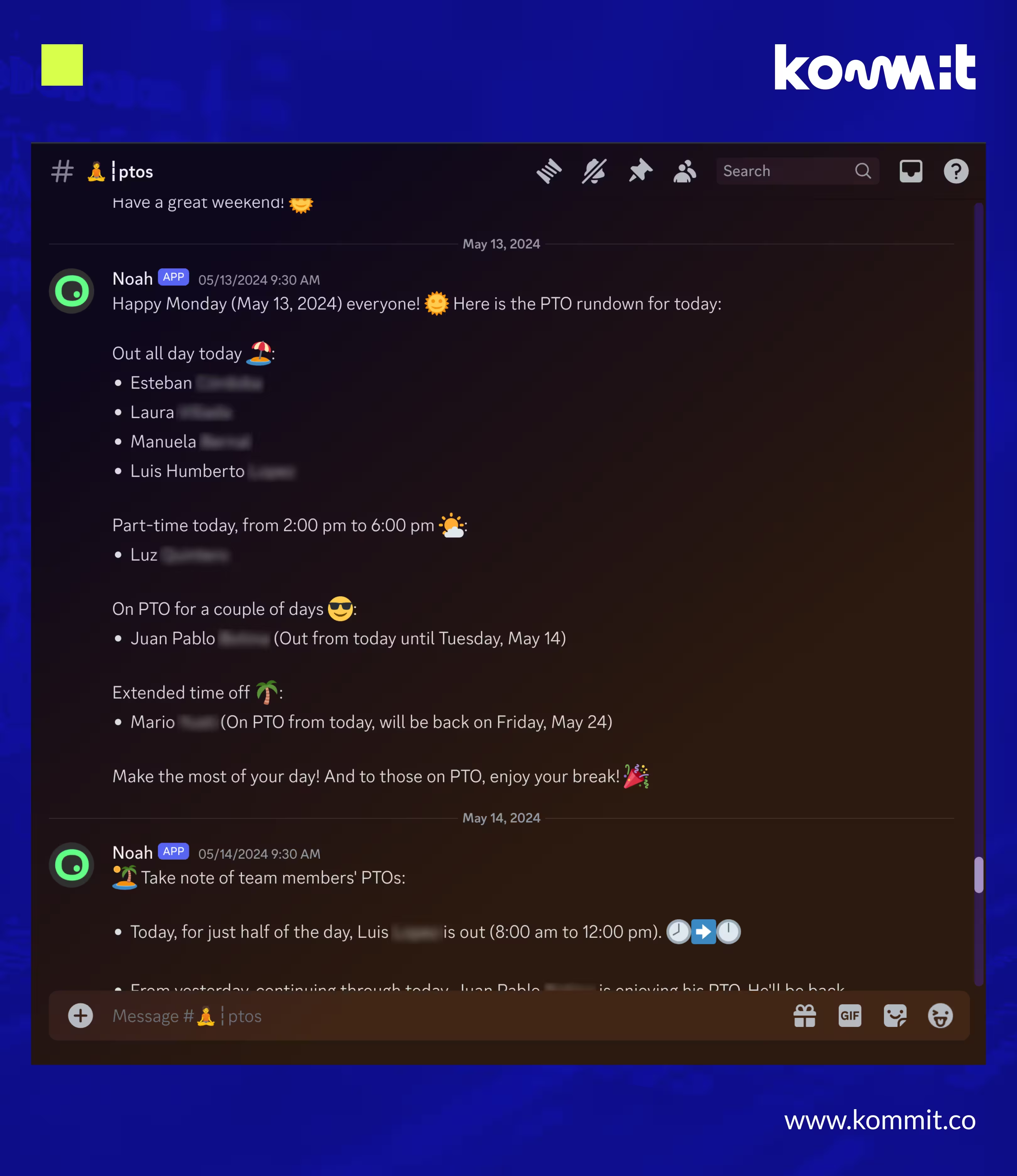

Let’s do some simple math to estimate how much waste a small automation removes. One of our automation cases is “Notify PTOs of the day,” which involves posting a message on a public channel daily informing who is on PTO and when the person is expected to return. Check this screenshot of how this automation case works at kommit:

Anytime I need to check if someone is on PTO for the day or for the next week, I click on the “ptos” channel. Before this automation case, I had to open another tab and navigate our internal system to find the same information. Let’s say it took 30 seconds longer. It’s a minimal change, but let’s do some math:

An employee who checks for PTOs twice daily will save 1 minute per day, 5 minutes weekly, and 260 minutes yearly—that’s 4.3 hours. If this employee costs the company $40 per hour, there will be $173.65 less waste during that year. Let’s assume a company with 100 employees and these same numbers to simplify this exercise. The result would be ~$17,365 less waste yearly.

Although unpolished, the exercise above illustrates what companies can achieve when investing in automation.

A useful automation program at a company must have complete support from the top. Scarce or timid efforts will fail because they typically don’t last and have minimal perceived benefits. Motivation will fade, and the resources spent on them will be lost.

After the top leaders entirely support the initiative, the next step is to define the principles that will guide it. Three one-page documents are required at this phase:

Although these will be short documents, building them will require several working sessions to keep them on the spot and useful. They will be the guiding map for executing the automation initiative.

The sum of many small improvements makes a difference and becomes a terrific competitive advantage. It works in big corporations, as in the case of AT&T with the Raindrops Project, and in small & medium-sized enterprises, as is the case of kommit with our BAS initiative.

In the end, although it is appropriate to evaluate how much we are wasting on things that can be automated, it is more revealing to calculate what advantage our main competitors have over us if they have an automation program running and we don’t.

The question isn’t whether to automate but how much competitive advantage we will sacrifice if we don’t.

Written by: Luis Hurtado, Founder @ kommit

Your team is busy—tasks move forward, deadlines get met (most times), work happens. But hidden beneath all this productivity is a quiet drain on your resources: those small, repetitive tasks that could (and should) be automated. How much valuable time are those tasks stealing?

April 2, 2025 Read more Hidden Productivity Drains: 5 Automations That Stop the LeakYour team is busy—tasks move forward, deadlines get met (most times), work happens. But hidden beneath all this productivity is a quiet drain on your resources: those small, repetitive tasks that could (and should) be automated. How much valuable time are those tasks stealing?

April 2, 2025 Read more Hidden Productivity Drains: 5 Automations That Stop the LeakThe market has responded with a wave of “No-Code” and “Low-Code” platforms promising to democratize automation for all. The appeal is obvious—who wouldn’t want that?

March 26, 2025 Read more Beyond the No-Code HypeThe market has responded with a wave of “No-Code” and “Low-Code” platforms promising to democratize automation for all. The appeal is obvious—who wouldn’t want that?

March 26, 2025 Read more Beyond the No-Code Hype© 2009 -2025 kommit, All Rights Reserved

Home Services Innovation About Us Blog Contact© 2009 -2025 kommit, All Rights Reserved

Home Services Innovation About Us Blog Contact